Conductivity

Properly understood and applied, conductivity is probably simpler to operate and maintain than any other analytical measurement. Each type of sensor has certain applications for which it is best suited. Most applications decisions involve the sensor more than the instrument. Modern instruments are so featured-packed that they will cover almost any application, but not so the sensors. They are where the measurement system meets the process.

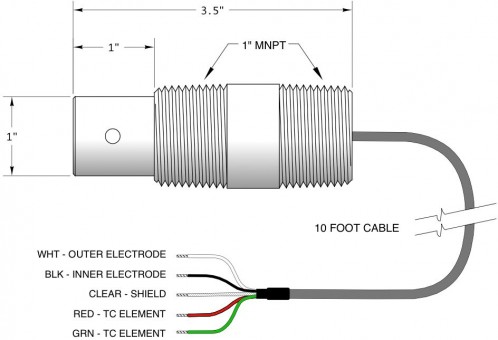

CS50 & CS60

- Double threaded body can be used for either submersion or insertion

- O-ring seals used on all versions for high on-stream reliability

- Can be used with many instrument brands by specifying the proper TC

These sensors are designed for use in general purpose applications up to 50,000 microsiemens, and provide outstanding chemical resistance. Open front end geometry resists clogging and reduces maintenance requirements to a minimum.

Application Notes

Wetted materials of construction are CPVC or Teflon/Kynar, with 316SS electrodes as standard. The option to select other metals as electrode materials provides an unequalled chemical resistance capability. Dual o-ring seals of EPDM increase sensor reliability and service life. The front seal absorbs the brunt of the chemical attack, allowing the rear o-ring to operate in a protected environment, and insure continued sealing. Cell constants from 0.1 to 2.0 are available. The ranges that can be achieved with these constants is dependent on the analyzer they are used with, but 10 to 50,000 microsiemens is the approximate area of use. TC selection is the key to using these sensors effectively with a variety of instruments.

TEMPERATURE COMPENSATION:

Available options include Pt1000, Pt100, 3K

BALCO, 8,55K NTC, Ni100 and many others.

Reference the make and model of instrument

for assistance in selecting the right element.

SPECIFICATIONS

MAX. PRESSURE/TEMP. RATINGS:

CS50 – 100 PSIG at 95ºC

CS60 – 100 PSIG at 120ºC

WETTED MATERIALS:

Electrodes – 316SS standard, Titanium, Monel, HastC, Nickel, Zirconium & more

Insulator – CS50-CPVC, CS60-Teflon/Kynar

O-Rings – EPDM FDA APPROVED

CONNECTIONS:

Process – 1″ NPT

Electrical – Stripped and tinned 24 gauge

CELL CONSTANTS:

2.0 / 1.0 / 0.2 / 0.1