Conductivity

Properly understood and applied, conductivity is probably simpler to operate and maintain than any other analytical measurement. Each type of sensor has certain applications for which it is best suited. Most applications decisions involve the sensor more than the instrument. Modern instruments are so featured-packed that they will cover almost any application, but not so the sensors. They are where the measurement system meets the process.

Toroidal Conductivity Sensors

- No polarization & resists fouling because no electrodes contact the stream

- Highest linear range, works better as conductivity rises

- Lowest maintenance because it is hardly affected by thin non-conductive coatings including oil

This sensor uses two donut-shaped transformers encased in a plastic body with a hold in the middle so that fluids flow through the center of both transformers and surrounds their sealed housing outside path.

Application Notes

The drive transformer has an AC voltage applied to its windings that includes an electric current flow in the conductive liquid inside the donut hole, that flow path being completed in the liquid surrounding the sensor tip. This external completion path is why the sensor is sensitive to its surroundings in process. The current flow in the fluid through the center of both transformers cores induces a current in the sense transformer that varies directly in proportion to changes in the fluid conductivity. That current is detected and displayed as solution conductivity.

TEMPERATURE COMPENSATION:

Pt1000 RTD

SPECIFICATIONS

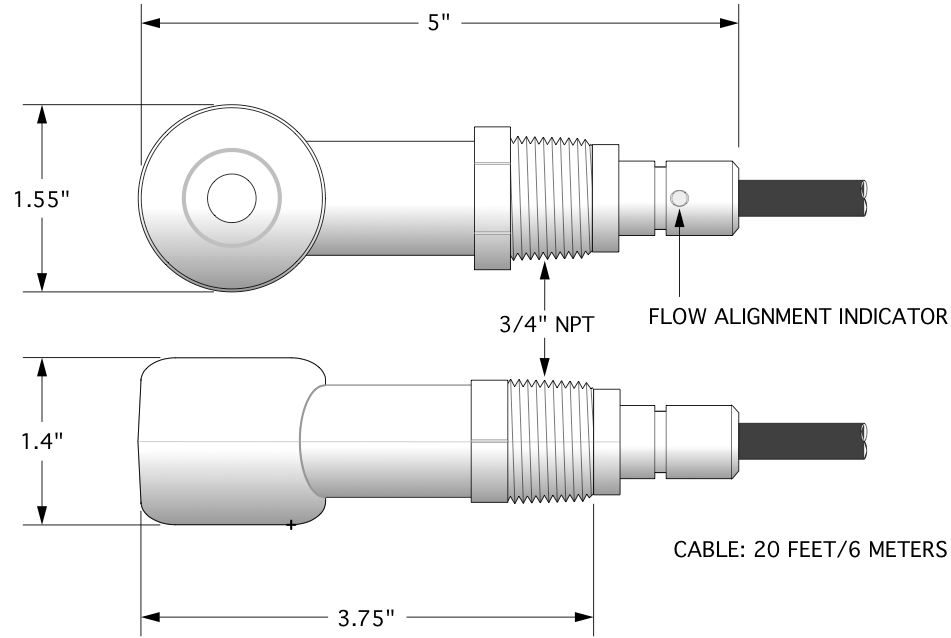

MAX. PRESSURE/TEMP. RATINGS:

200 PSIG at 105ºC

WETTED MATERIALS:

Block Copolymer Polypropylene

CONNECTIONS:

Process – 3/4″ MNPT

Electrical – 20ft (6m) cable, stripped and tinned

CELL CONSTANT:

20/20 winding K=4.8

40/15 winding K=7.3