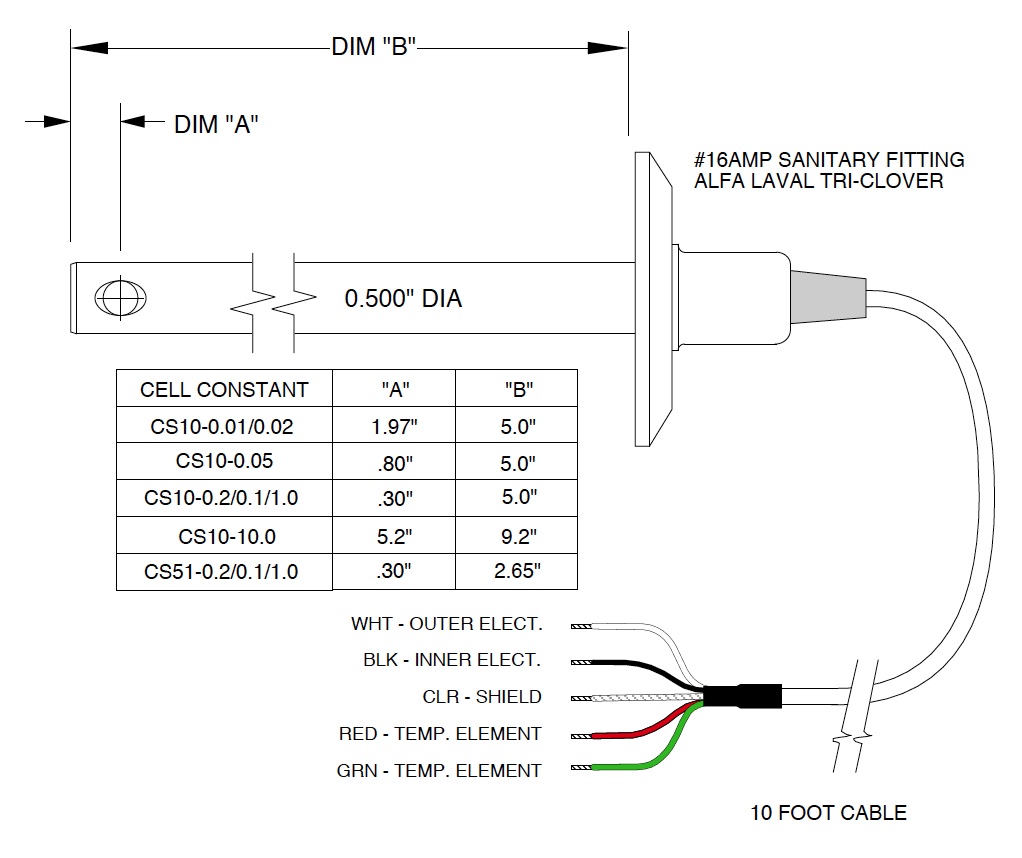

CSxx-TC

- Designed for insertion into Ladish or Tri-Clover fittings

- O-ring seals used on all versions for high on-stream reliability

- Steam sterilizable

The CS10, CS51 and CS52 sensors are welded to blind flanges of customer specified size, and can then be inserted into standard tee fittings in sanitary systems using Ladish or Tri-Clover fittings.

Application Notes

Wetted materials of construction are 316L stainless steel and teflon, with double redundant EPDM o-rings. The process side o-ring is the only one in contact with the stream, allowing the back o-ring to maintain reliable sealing, free from chemical attack. TC elements are potted in the body itself. Leads are 10′ standard. Process connections are Tri-Clamp sanitary flanges or customer specified size. The insertion depth can be modified on request to obtain proper positioning in a specific installation. The sensor is built for clean in place service, either steam or sterilizing chemicals. All wetted materials are FDA compliant, and USP Class VI is available.

TEMPERATURE COMPENSATION:

Available options include Pt1000, Pt100, 3K

BALCO, 8,55K NTC, Ni100 and many others.

Reference the make and model of instrument for assistance in selecting the right element.

SPECIFICATIONS

MAX. PRESSURE/TEMP. RATINGS:

100 PSIG at 130ºC

WETTED MATERIALS:

Insulator – Teflon

O-Rings – EPDM FDA APPROVED

Electrodes- 316LSS Standard

Fitting – 316LSS

All materials are FDA compliant

CONNECTIONS:

Sanitary Flange 1/2″ to 2-1/2″

CELL CONSTANTS:

10.0/ 1.0 / 0.2 / 0.1 / 0.05 / 0.02 / 0.01